Smoke Shaft Airtightness

A smoke shaft is a common term for a ventilation system within lobby areas of tall buildings. The shaft has closable smoke-controlled dampers on each floor; only the damper on the floor with the fire is open to enable smoke extraction from the lobby to support tenable conditions.

Why

The smoke shaft needs air testing before installing and commissioning the ventilation equipment. Since there is no standard to adhere to on mechanical smoke shafts, most are tested to 3.8m³/hr/m² at 50Pa, which is the Colt standard. However, following the manufacturers’ recommendations and confirming specifications is advisable before work begins.

In general, smoke shafts have an extremely high failure rate, so it is recommended to plan an effective air-tightness strategy from the start. We can offer pre-test inspections by installing a fan and using non-toxic smoke to show air leakage areas.

When

As previously said, the best time to test is once the shaft is completed before installing the ventilation equipment and lobby dampers. Ensure the head of the smoke shaft has been air-sealed and each damper opening temporarily sealed using Corex or Celotex.

How

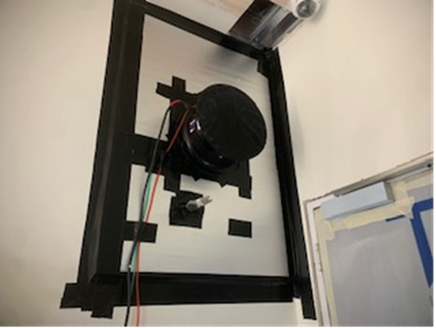

As per the building air tightness test, the shaft is assessed using a Blower door fan fitted onto one of the damper openings.

Outcome

In case of an air test failure, remedial work may have to be conducted by rope access teams with confined space training; we recommend Stroma Specialist Access for this tasking.